Introduction

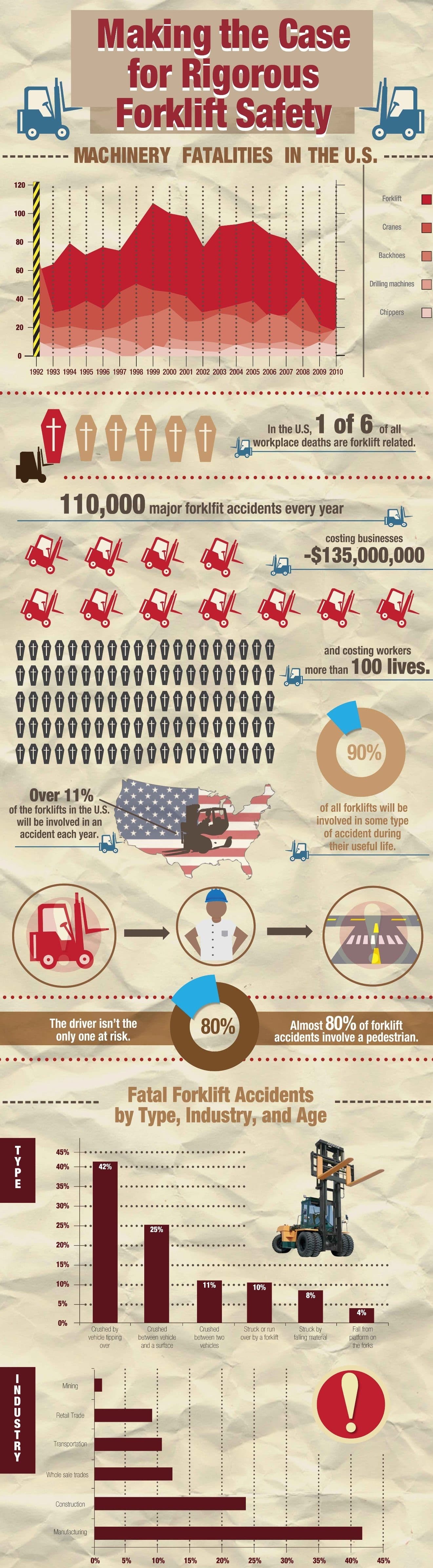

According to many sources, forklift accidents account to a number of deaths, injuries and thousands of damaged goods. One specific company which has a long history of providing a cutting edge supply chain wanted a system to improve their material handling safety and in order to satisfy their requirements SenzMate’s Forklift Monitoring System played a major role.

Business Case

Damage to the goods can be caused due to many reasons, for example forklift overturn which can be a result of carrying too much load at once, taking irregular paths from point A to point B or even due to careless driving by the assigned driver. Other downsides are, unwanted lengthy idle time which means the machine is working but not operating and unwanted acceleration during transportation.

Solution

In order to tackle these problems, SenzMate’s Forklift Monitoring System provided three main functionalities to improve material handling safety. First, forklift’s status detection which includes movement, vibration and impact sensing. The other two are that it detects the forklift’s location at all times and tracks the forklift driver’s driving behavior to ensure safe driving patterns. Apart from these features it includes other necessary attributes like, keeping data history, generating instant reports and issuing on-time SMS and Email alerts.

Action Taken

With all these features, SenzMate provided a monitoring system with web and mobile based applications to seamlessly access all data related to all forklifts within that specific organization. With the aid of GSM connectivity, Real-Time communication and Edge computing, all the features supplied by the monitoring system are readily and easily available. The system tracks the idle and productive times to provide a graphical view in the applications itself. The impact sensing feature supply data like the magnitude of impact, basic variations to trigger customized alerts to the relevant individuals. In addition to movement tracking, the system pinpoints the location of all forklifts with their vehicle movement heat maps and shows the travel path graphically, which helps to optimize the routes. With the integration of driver behavior tracking, the safety of the pallets can be ensured as well.

Results

With the integration of the monitoring system with impact sensing, location tracking and driver behavior monitoring, safety of the pallets and its goods have been improved drastically. In house efficiency has been increased at remarkable rates and the general objective, which is to provide the end customers with high quality and damage free goods has been achieved. Visit "Indoor forklift localization using Bluetooth low-energy beacons" techblog